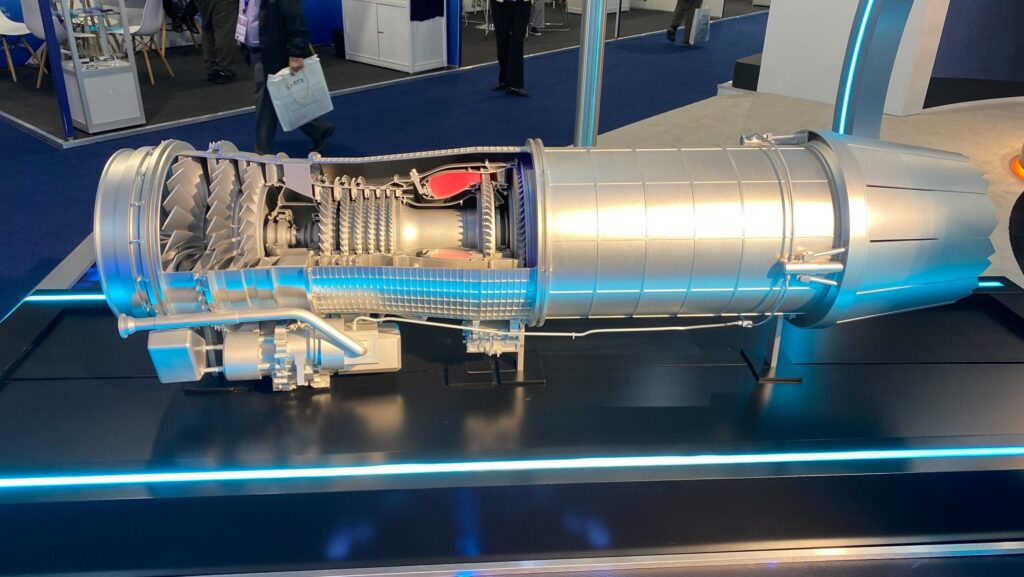

The manufacturing of Northrop Grumman solid rocket motor cases for the Next-Generation Interceptor (NGI) program is a significant achievement that demonstrates Northrop Grumman’s expertise and robust designs and manufacturing capabilities. (Northrop Grumman photo)

In this Q&A with Northrop Grumman’s Lisa Brown, vice president and program director for Next Generation Interceptor (NGI), we discuss the recent NGI milestones, their near-term roadmap, the team’s production readiness and the digital engineering aspects driving the program.

Breaking Defense: What are the global missile threats we’re seeing today and expect tomorrow that necessitate the development of the Next Generation Interceptor for defense?

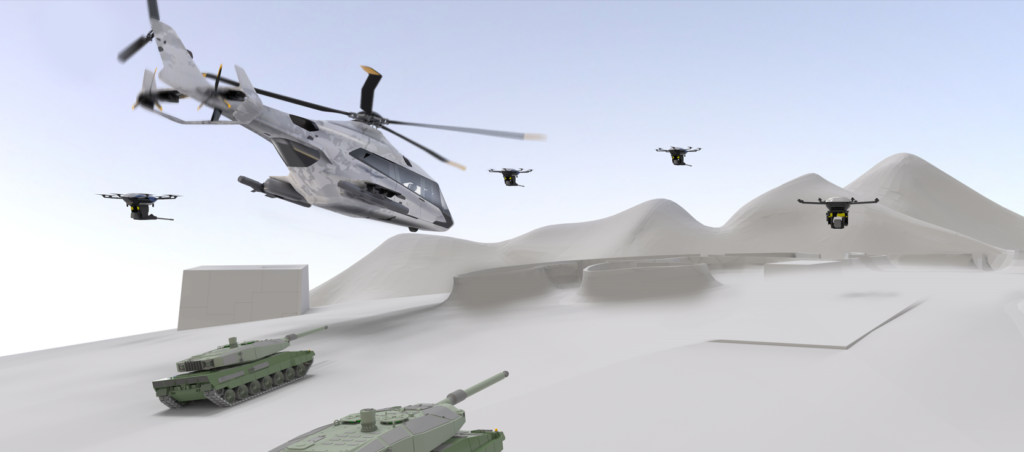

Brown: The existing Ground-Based Midcourse Defense (GMD) system was fielded decades ago, and anyone who watches the news knows how much our potential adversaries are ramping up their testing. The purpose of NGI is to counter evolving ballistic missile threats, and the more people that start playing in that field the more diverse the different threats may be. Even though someone may not have an intercontinental capability now with their ballistic missiles, it doesn’t mean that there aren’t indications that they could in fairly short order.

Creating a solution that’s able to defend against various designs of advanced threats is critical, and certainly will be an improvement over what we have currently fielded.

Breaking Defense: Describe the steps you’re taking to produce these systems at scale when the time comes? What does it mean when you say you’re production ready with manufacturing facilities fully operational?

Brown: NGI is of global strategic importance, which is why production and manufacturing readiness play a central role in our NGI solution. Building a system of this scale required that we assembled a team that represents the best the industrial base has to offer in terms of both technology and the ability to produce that technology at scale. We have done that. We are now leading that team through development at an outstanding pace while never taking our eye off ensuring that we’re ready to transition that design to production once development is complete.

One of my favorite bosses drilled into my head early in my career that production begins with the first day of design. That is exactly what we are doing with our NGI solution. We hold ourselves and our entire supply chain to a high standard in this area and we manage that as a matter of routine on this program. You can have a great design, but if you can’t get it into the field at scale, you haven’t actually delivered what the warfighter needs on time. That’s why it’s so important that we deliver a low-risk path to both field NGI and reach targeted production rates by 2028 or sooner.

For example, I think we can all agree that solid rocket motor (SRM) technology will need to be deployed on an unprecedented scope and scale to defeat evolving threats. Mission-critical national security and defense programs like NGI require capable SRMs, and Northrop Grumman has been using advanced technologies to deliver flight-proven propulsion for nearly 70 years.

We are utilizing Northrop Grumman propulsion systems business in Utah, a recognized national security asset, to build all three stages of our booster. I’m excited to share that we have all three stages of our solid rocket motor design going through static firing within the next several months, subject to government test facility availability.

Right now, we have our third stage solid rocket motor at Arnold Engineering Development Complex (AEDC), in Tennessee, for testing. You need to be there to get in line, so getting our systems there and ready to be tested is important. It’s been there since December awaiting its place in the test sequence this Spring. Our second SRM test motor is ready to ship to AEDC where it will also enter the queue for a static test fire, and our third solid rocket motor will be tested in the coming months out at our Northrop Grumman propulsion facility in Utah.

Our state of the art manufacturing facility in Chandler, Arizona is being used for avionics and integration of the all up round. That facility designs one-to-two new missiles per year and has over 65 fielded launch-booster assemblies currently in use.

Our NGI program office is headquartered at our Northrop Grumman Redstone Gateway campus, at the gates of Redstone Arsenal in Huntsville, Alabama, and close to our government customer. Redstone and the Huntsville community is incredibly important to us — not just because our customer is here — it’s where, in the coming months, we will be integrating our first NGI ground test missile as we prepare for more advanced testing of the entire all up round design.

The entire Northrop Grumman team is using certified, existing production and manufacturing facilities — where we’re working on similar concepts and capabilities — to manufacture our NGI solution. We are fully staffed with a deep bench of experienced, mission-focused teammates, and we have dedicated the capacity needed for NGI baseline production plans throughout these facilities and ensuring our suppliers have done the same.

As I mentioned, we have done this kind of work for decades and we selected suppliers who produce components for similar programs in existing facilities to deliver that low-risk path to getting NGI to the field on time. So, to sum up, when you ask about our production and manufacturing readiness, our team is building interceptors, not buildings.

Northrop Grumman delivered its Next Generation Interceptor (NGI) Stage Three solid rocket motor (SRM) to Arnold Air Force Base, TN ahead of schedule for a full static fire test in early 2024. The SRMs will help power the NGI booster, and data from the static test will help anchor NGI’s solid rocket motors ballistic predictions, informing other SRM designs before entering qualification testing. (Northrop Grumman photo)

Breaking Defense: Bring us up to date on milestones for the NGI program.

Brown: We continue to demonstrate how our NGI solution is lowering risk for the Missile Defense Agency. We conducted our Preliminary Design Review (PDR) Jan. 22-26, passing at the end of the five-day event, a year ahead of our contract schedule. And we received our Knowledge Point 1 (KP1) letter from the customer shortly thereafter confirming that we’d satisfied all exit criteria for that phase of the program.

We will continue to accelerate our design, building and testing even more hardware – working in open and transparent partnership with our customer, our strategic partners, and our small businesses teammates.

The next major development milestone is our Critical Design Review which is planned for second quarter of 2025. Of course, our team does a great job of identifying schedule opportunities and is constantly evaluating accelerating the date if we can do it sooner given the importance of the schedule on this no fail mission.

Northrop Grumman is leveraging over six decades of propulsion expertise for its Next Generation Interceptor (NGI) solution. The company’s solid rocket motor capabilities will make its NGI solution a highly reliable asset for National defense and will provide drastically enhanced capabilities that will defend the U.S. homeland from Intercontinental Ballistic Missile (ICBM) threats, as part of the Ground Based Midcourse Defense (GMD) system. (Northrop Grumman photo)

Breaking Defense: You made the comment that production begins the first day of design, but now the first day of design is very different than it was years ago because of digital engineering.

Brown: With a system as complex and important as GMD, which NGI will be a part of, it’s critical that we have a way to manage this complexity and accelerate the development process to take NGI from concept into the field. We do this through digital engineering.

On NGI, digital transformation has allowed us to transform the way we work. The tools we have access to now allow us to collaborate in real time with our teammates and customers far more efficiently than we ever have in the past. Beyond that, digital engineering is shortening the cycle time needed to iterate on the design and mature it much faster than we could before.

We call this process ‘early cycles of learning’ and it directly translates to a more mature design earlier in the program. We use this process to learn lessons and drive out issues in the design much sooner in development when it’s faster and less costly to do so.

One of the ways we do this is by building high fidelity virtual representations of our missile, sometimes called digital twins, that we use to refine our design and run analysis without needing to spend the resources and time to do this after the hardware is built. It’s great not just for the engineers but also for our technicians who assemble the components and will ultimately be responsible for emplacing and maintaining the system once it’s built.

![The sights from the 2024 Farnborough Airshow [PHOTOS]](https://centurionpartnersgroup.com/wp-content/uploads/2024/07/IMG_8722-scaled-e1721930652747-1024x577-hZjwVb-500x383.jpeg)