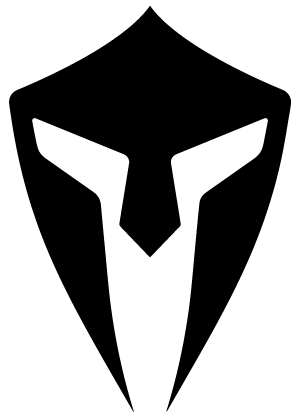

Green Berets assigned to 5th Special Forces Group (Airborne) conduct sniper training from a MH-6 Little Bird with the 160th Special Operation Aviation Regiment (SOAR) at Fort Campbell, Kentucky on March 27, 2024. (U.S. Army photo by Staff Sgt. Brandon J. White)

SOF WEEK 2024 — The Army’s surprise decision earlier this year to cancel the Future Attack Reconnaissance Aircraft (FARA) program has breathed new life into Boeing’s A/MH-6 Little Bird for special operators, with one Special Operations Command (SOCOM) official describing an ongoing enhancement as tantamount to a “resurrection.”

The Block III upgrade in process for the Little Bird designates the chopper as the A/MH-6R. But following the end of FARA, “that R is not a Romeo,” said Steven Smith, SOCOM’s rotary wing program executive officer, at the SOF Week conference here in Tampa on Tuesday. “I’m calling it Little Bird ‘resurrection.’ It’s the future for Little Bird.”

SOCOM had previously planned for FARA to take the role of the AH-6, but the program’s cancellation “changed our equation,” Smith said. “And so now we don’t have that solution available.”

Smith explained the “R” upgrade effort incorporates a new fuselage that boosts the Little Bird’s design limit to 5,000 pounds. The overhaul further includes new equipment like a smaller mission computer and interfaces for next-gen comms. Smith said the overarching effort should carry on through the 2031 to 2032 timeframe.

“That’s about a 15-year life we’ve predicted on that fuselage. I think that gives us a little bit of time to allow the Army to figure out what it’s going to do for its scout requirement,” Smith said. “So FARA has been canceled, but the requirement itself to have something that can see, sense, fix adversaries over the horizon, that still exists. And so whether that’s going to be unmanned systems or some sort of manned-unmanned teaming, we’ll have that time to figure that out. And then we’ll do incremental changes along the way.”

The FARA cancellation isn’t the only aviation fallout from the Army’s rotorcraft shakeup. Smith said SOCOM is also feeling the effects of the Army’s decision to delay production of the Improved Turbine Engine Program (ITEP). The command was expecting to incorporate ITEP for the its specialized MH-60M Black Hawk helicopters made by Lockheed Martin subsidiary Sikorsky.

“We had planned to do some work with the ITEP engine. But that was predicated on the Army getting that qualification done first,” he said. “So we know that they’re going to continue their qualification of that engine, but they’ve delayed the procurement so we think there’s a four- to five-year shift based on the aviation re-balance.”

Even though platforms like the Black Hawk may now have to stick around until the 2050s or longer, Smith still emphasized the value of the Army’s larger Future Vertical Lift (FVL) effort that encompasses other elements, like the in-development Future Long-Range Assault Aircraft.

Specifically, Smith described the value of the FVL “ecosystem,” which he said SOCOM was “counting on” for new improvements like a modular open system architecture that can help foster goals like a common Army helo cockpit. That feature is expected for future aircraft, and though SOCOM would like it for legacy platforms, Smith said the command is “not really sure yet” how that will work.

The command has many ambitions, Smith said, but a tight budget limits what’s realistic. That’s where, he said, industry comes in.

“I need your help. SOCOM cannot do this alone. If you look at the percentage of the SOCOM budget compared to the overall national defense budget, it’s miniscule,” he told industry attendees. “So I need your investment in the right technologies to help us field advanced capability.

“But additionally, I need your help with controlling cost and with quality assurance. And so since COVID, we’ve seen over a 40 percent growth in material cost,” he continued. “We’ve got to find a way to be able to make things in this country again, affordably.”

Smith also implored industry to accept lower margins on their sustainment work — often the most costly portion of a program and a lucrative opportunity for vendors — for the good of national security.

“We’ve got to do something about obsolescence. Just because you can’t make 40 percent on a product doesn’t mean that we shouldn’t be supporting that,” he said. “There’s got to be some folks that are out there willing to make a 10 percent margin and keep things working.”